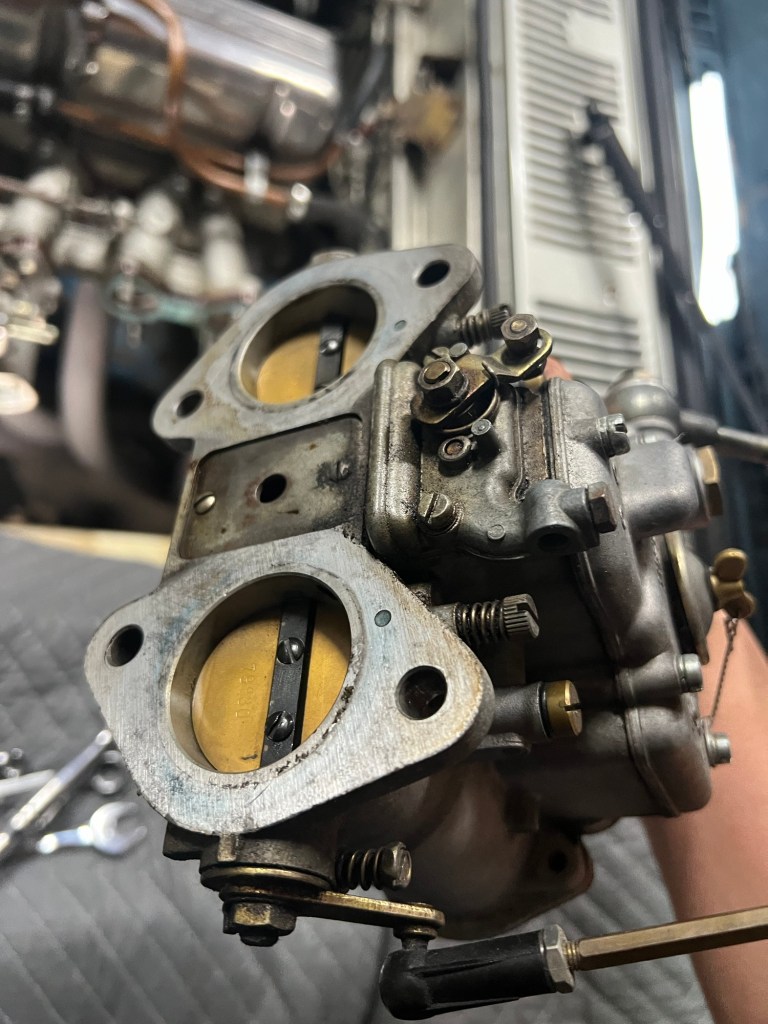

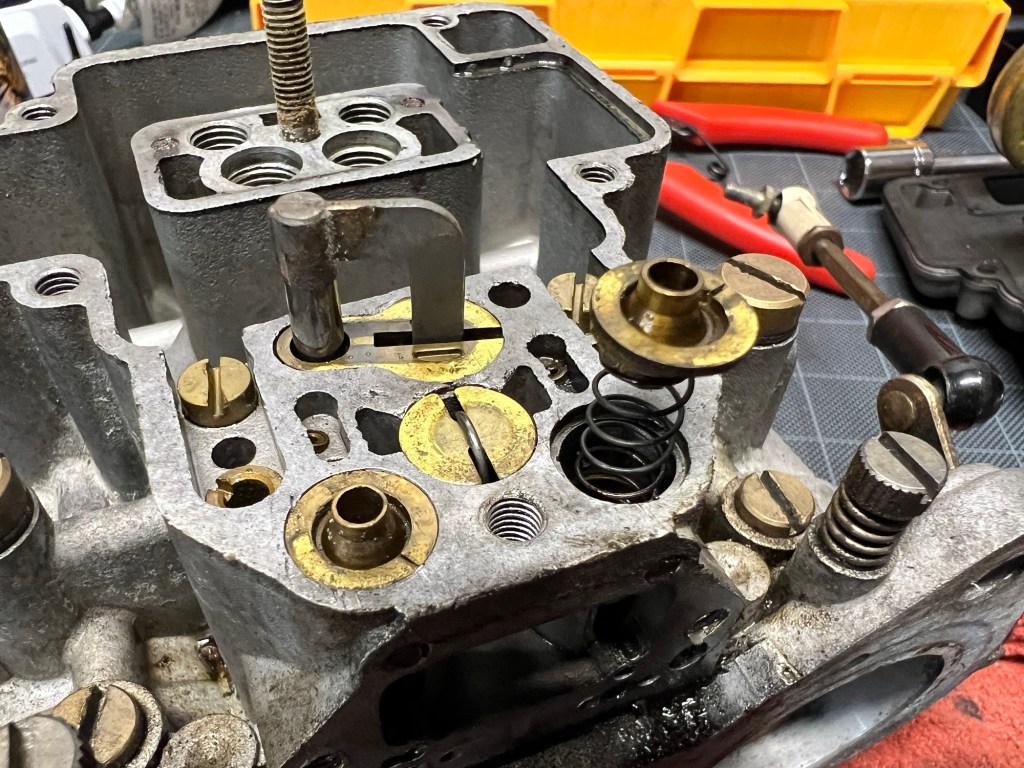

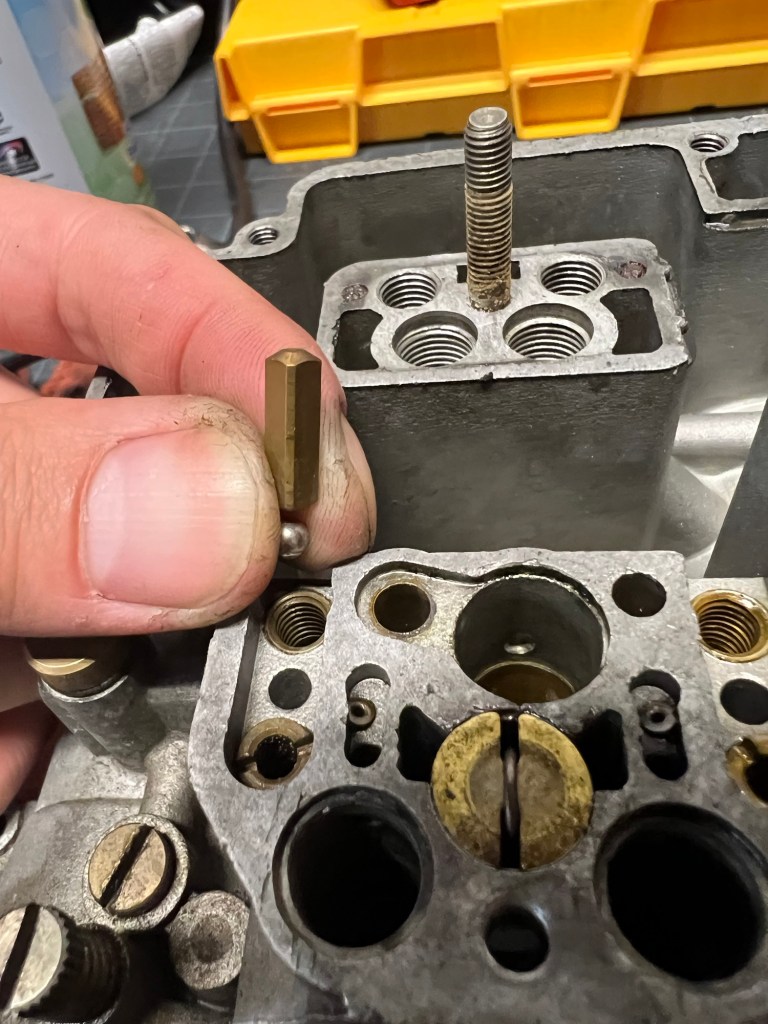

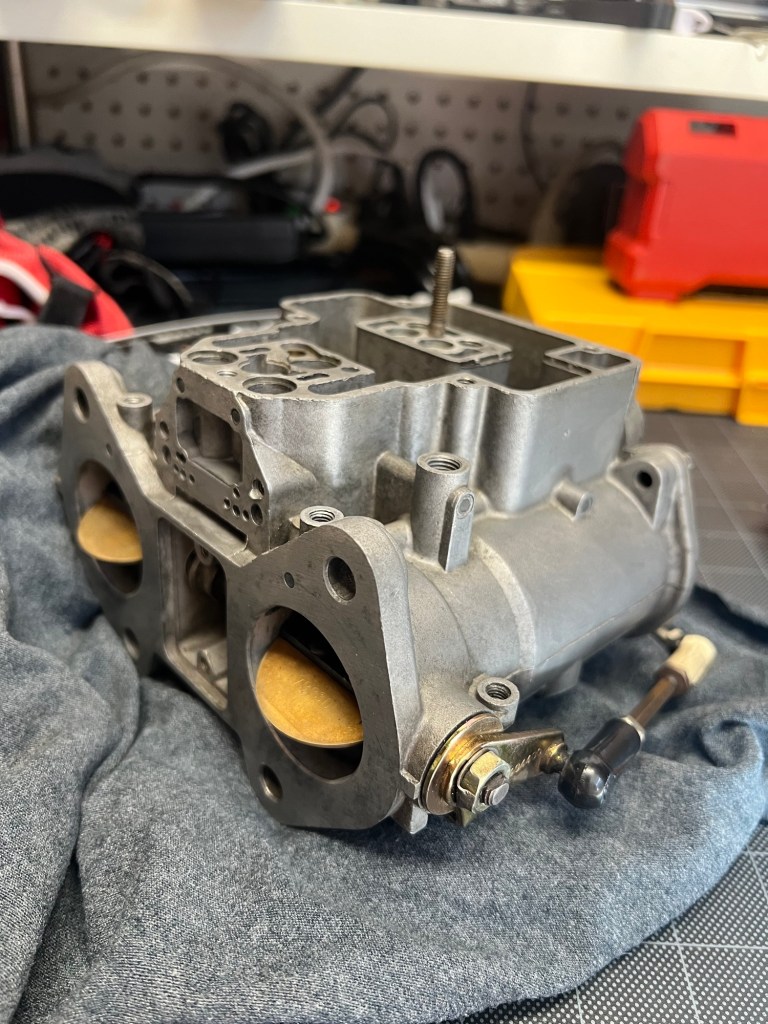

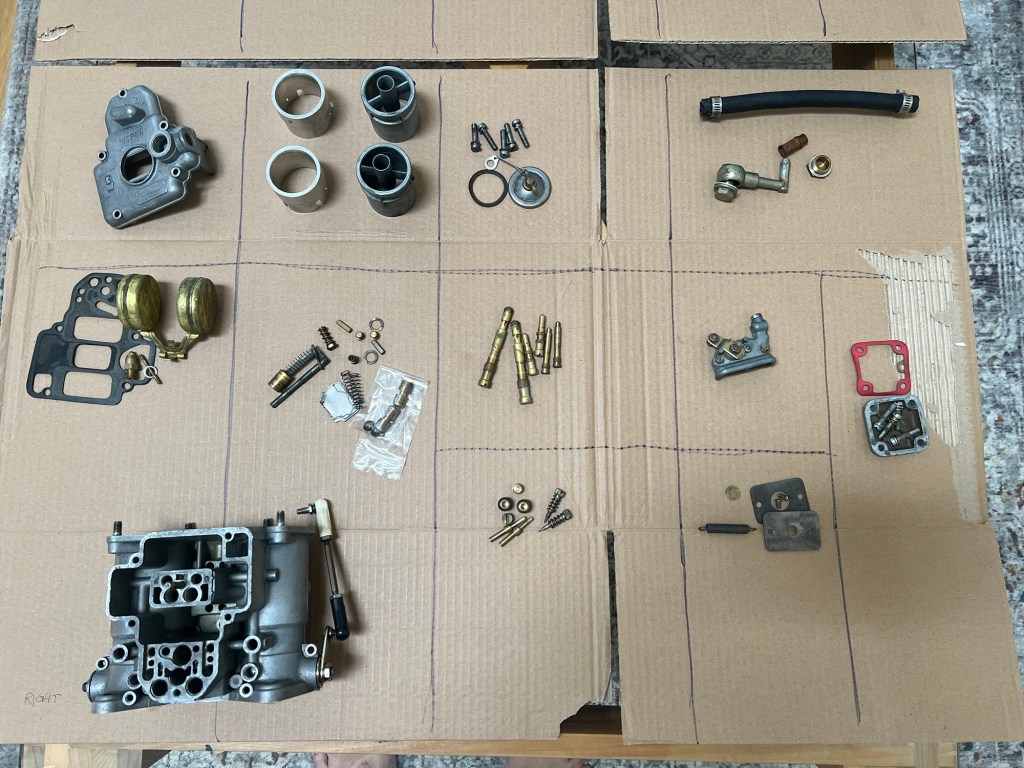

After searching online for shops that rebuild Weber 40 DCOE carburetors it was clear that not too many places offered that service anymore. The shops that I found were also going to cost a lot and needed to be shipped far away. I decided to take a shot at rebuilding the carbs by myself after seeing some YouTube instructional videos. It was intimidating at first because of the amount of parts but staying organized and grouping the parts really helped. It took me a few days to disassemble, clean all the parts with carb cleaner and gasoline, and polish the outer carb housing. I found a few parts that were stuck because of the old gasoline gumming them up and seizing the parts like the pump valve and ball and the float needle valve. Some of the threads had rust so I cleaned out the hole and brushed the threads. I had to replace 4 cross threaded starter jets. I found a shop in Netherlands that was affordable and offered shipping to the United States. Not a lot of places offered parts for the older Italian style Webers.

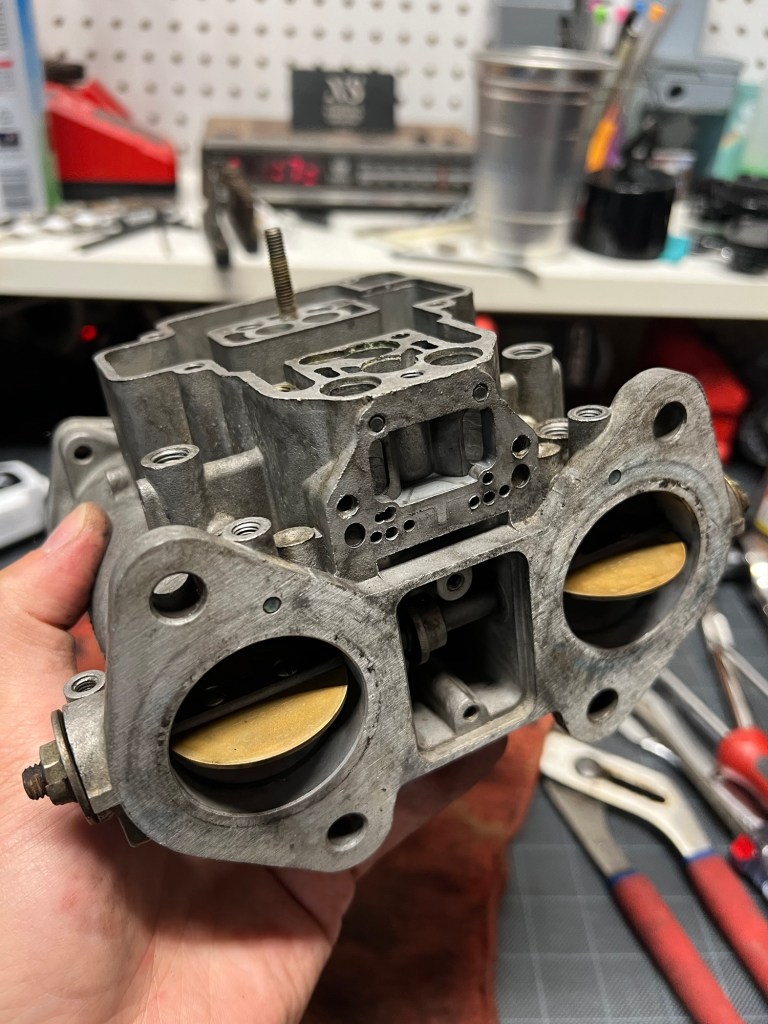

The rebuild Redline kit arrived and I started assembling the carbs with new gaskets and replacement parts. The kit came with a gasket for the intake manifold but I also needed a set for the spacer to the carbs. It was pretty satisfying to see everything go back together.

While I was close to putting the carbs back in my friend Spencer calls me and says he can help me get the Hako registered! What a blessing. I can’t thank him enough.

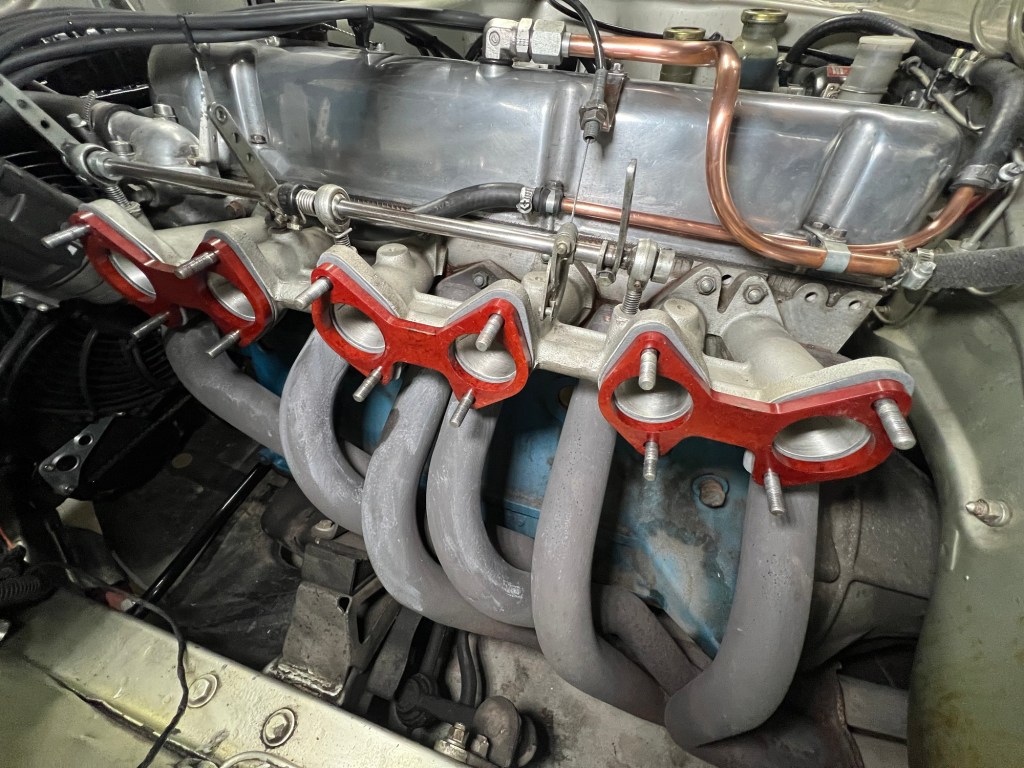

Now with the license plate on the car I was really looking forward to test driving the Hako but I had to still wait for the seats. I put the carbs and gaskets back on the engine and couldn’t help but notice how much cleaner it was. Now time for the big event, starting her up!

As you can tell I was stoked that it started after only a few cranks. It sounded healthier than before but it was idling around 3,000 rpm! Time to mess with the linkage and air/fuel ratio to get the idle down. I got it to 1,000 rpm and she seems happy for now.

Leave a comment